Fractographic Image Analysis Using

Computer Vision and Deep Learning Methods

Many mechanisms operate under dynamic loading regime during daily use, e.g., helicopter rotors, electric saws, engine parts, etc. If a structure breaks, the company that produced the machine or the operator of the device investigates the failure cause. The insights may help the company plan ahead for critical events, by updating the maintenance policy or the operating instructions or even lead to redesigning the whole mechanism.

Many resources are directed toward a fractographic analysis, which could help to discover the failure cause. In some investigations, one of the crucial steps of the fractographic analysis is the part’s loading history estimation.

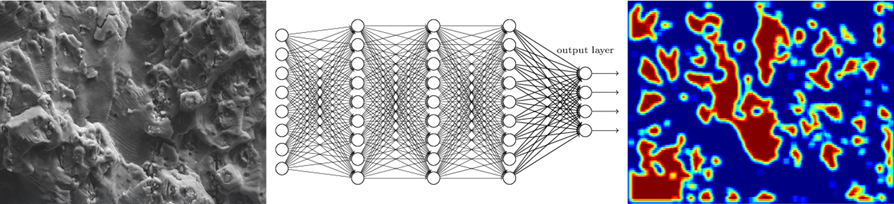

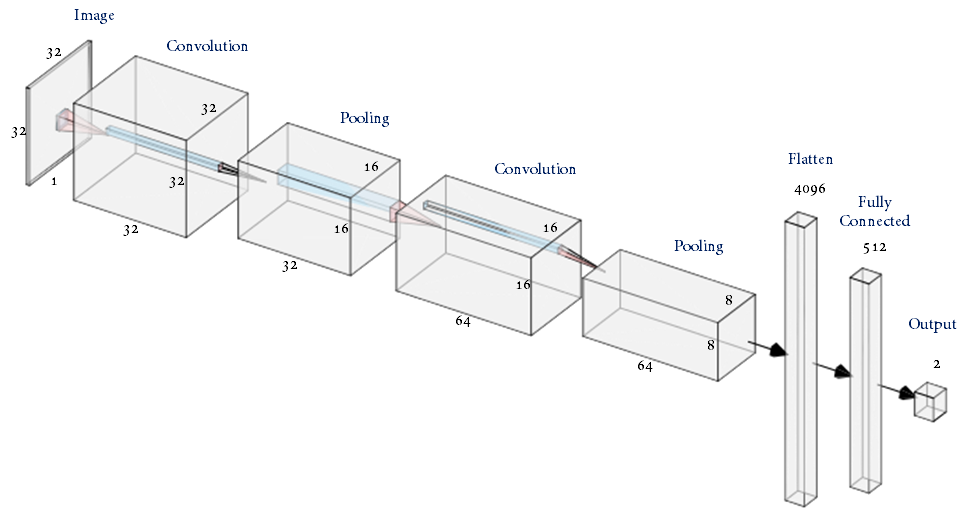

Today, most of the fractographic analysis is being executed manually, so failure investigation process takes a long time and demands a fair amount of resources. In this study, we propose to computerize one of the most challenging and time-consuming stages of the fractographic analysis process: locating fatigue striations on SEM (Scanning Electron Microscope) images. FS (Fatigue Striations) are lines appear on the fracture surface, which created by crack propagation under a cyclic loading regime. These lines appear in groups, and those groups are the most significant indicator of fatigue failure on fracture surfaces (on the microscopic level).

The advantage of the detection algorithm developed in this study is that the FS groups texture properties does not define manually. Defining the FS groups unique features may be complicated, especially using basic computer vision tools which are not built to find abstract features.

In this study, we used DL (Deep Learning) to define the FS groups features. DL is a branch of machine learning based on a set of algorithms that model high-level abstractions in data. Using a dataset of marked images, DL is capable of building image-processing mathematical models which define complex textures and patterns, that sometimes are almost impossible to identify by classic computer vision methods.

Automatic detection of FS on the fracture surface may reduce the fractographic analysis time from days to minutes. This enormous time reduction would allow the execution of the full fractographic analysis more often, a fact that could improve the safety of critical mechanisms (such as plain part) – which eventually prevent fatal accidents.